- Products

- Resources

-

-

Vicks products are available for purchase online and in-store at most major retailers.

-

-

- Support

-

-

VICKS SUPPORT

View product-specific FAQs & videos

-

-

- Products

- Resources

- SUPPORT

- Warranty Registration

- Contact Us

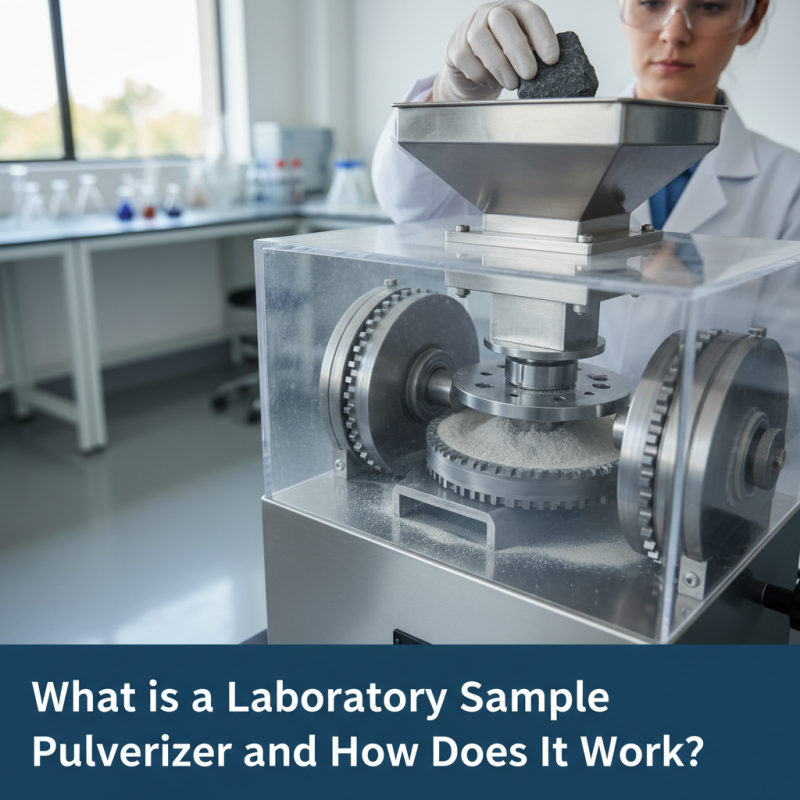

What is a Laboratory Sample Pulverizer and How Does It Work?

In the realm of material testing, the laboratory sample pulverizer stands out as a vital instrument. Dr. Jane Wilson, an expert in laboratory equipment, once stated, "A reliable pulverizer can dramatically improve the quality of test samples." This highlights the importance of proper sample preparation in laboratories.

A laboratory sample pulverizer effectively grinds bulk materials into fine powders. This process is crucial for obtaining accurate analytical results. The device uses mechanical forces to crush, shear, and grind the samples, ensuring homogeneity. However, not all pulverizers deliver equally satisfactory results. Some may introduce contaminants or fail to achieve the desired particle size.

Moreover, the user must also be aware of the machine's limitations. Improper use can result in uneven samples, leading to misleading data. Understanding how a laboratory sample pulverizer operates and its appropriate applications can significantly enhance research efficiency. Therefore, careful consideration of equipment choices and operational procedures is paramount for laboratory success.

What is a Laboratory Sample Pulverizer?

A laboratory sample pulverizer is a vital tool in scientific research. It helps in reducing materials to a fine powder for analysis. This device is essential for labs that require precise measurements and consistent results. Typically, it can process various materials, including rocks, minerals, and organic substances, all while maintaining sample integrity.

The pulverizer utilizes mechanical force to crush and grind samples. It often features adjustable settings for particle size. Researchers appreciate the ability to control this aspect closely. The machine usually operates quietly but can generate heat if used continuously. That might affect sensitive materials, so monitoring is crucial. Each time it is used, there exists a chance of contamination or loss of material if not handled properly.

In practice, users sometimes encounter difficulties. For example, improper loading can lead to uneven grinding. Cleanliness is essential; leftover particles can skew results. These factors highlight the need for careful operation and maintenance. Although the pulverizer is robust, it demands respect and attention to achieve reliable outcomes.

Key Components of a Laboratory Sample Pulverizer

Laboratory sample pulverizers are essential tools in various industries, particularly in materials testing and geological analysis. Their primary function is to reduce materials to a finer consistency for further testing.

The key components of a laboratory sample pulverizer include the grinding chamber, crushing plates, and a drive mechanism. Each part plays a crucial role in ensuring efficient and consistent sample preparation.

The grinding chamber is where the actual pulverizing occurs. It is designed to hold the material securely while it is subjected to mechanical forces. Typically, this chamber can be lined with hard materials to reduce wear.

Crushing plates, often made from hardened steel or ceramic, effectively break down samples. According to industry data, proper maintenance of these components can enhance pulverizer life by up to 30%.

The drive mechanism, usually electric, powers the grinding process. It is vital for achieving the desired speed and uniformity in grinding.

However, the power output can sometimes be unreliable, leading to inconsistent results. This inconsistency highlights the need for regular calibration and user training. Moreover, some pulverizers generate excessive heat during operation, which can affect sample integrity.

Being aware of these imperfections is crucial for ensuring accurate analysis in laboratory settings.

How Does a Laboratory Sample Pulverizer Operate?

A laboratory sample pulverizer is an essential tool in material analysis. It operates by finely grinding and blending various substances into a homogeneous powder. The process typically involves a motor-driven mechanism that exerts pressure on the sample material. As a result, it can quickly reduce the size for accurate testing and analysis.

Using a sample pulverizer can significantly enhance efficiency in laboratories. According to industry reports, the use of pulverizers can increase sample processing speed by up to 40%. This reduction in time is critical for researchers working with limited resources. Moreover, the uniformity of the particle size is vital for reproducibility in experiments, leading to more reliable results.

However, operating these machines is not always straightforward. Misalignment or incorrect settings can lead to suboptimal results. For instance, particles may vary in size, affecting analysis accuracy. Regular maintenance is crucial to ensure consistent performance. A well-calibrated pulverizer is vital to achieving the desired fineness. Despite these challenges, the benefits of utilizing a laboratory sample pulverizer often outweigh the drawbacks for many scientific applications.

What is a Laboratory Sample Pulverizer and How Does It Work?

| Feature | Description | Applications |

|---|---|---|

| Type of Pulverizer | Laboratory Sample Pulverizer | Material testing, research and development |

| Grind Size | Adjustable from coarse to fine | Sample preparation for analysis |

| Material Compatibility | Minerals, ceramics, chemicals | Research across various fields |

| Operation Principle | Crushing and grinding through mechanical force | Preparation of samples for particle size analysis |

| Power Source | Electric motor | Convenient for lab setups |

| Typical Operators | Researchers, lab technicians | Quality control and research facilities |

Applications of Laboratory Sample Pulverizers in Various Industries

Laboratory sample pulverizers play a crucial role in various industries. They provide precise and consistent size reduction of materials. Common applications include mining, pharmaceuticals, and food processing. In mining, pulverizers help analyze ore samples, preparing them for further testing. This ensures the accuracy of assays and mineral content analysis.

In the pharmaceutical industry, these devices aid in drug formulation. They allow for uniform particle sizes, essential for consistent dosing. However, achieving the perfect consistency can be challenging. Sometimes samples may clump together, affecting outcomes. Ongoing adjustments are needed to optimize the process.

Food processing also benefits from laboratory sample pulverizers. They assist in grinding spices, grains, and other foods. This enhances flavor consistency in products. Yet, finding the right settings can require trial and error. Operator experience plays a significant role in refining results across different substances. Each application reveals unique challenges, reminding us that constant improvement is vital.

Applications of Laboratory Sample Pulverizers in Various Industries

This bar chart illustrates the frequency of laboratory sample pulverizers used across different industries. The highest usage is observed in Environmental Testing and Mining, reflecting the diverse applications in various fields for sample preparation and analysis.

Maintenance Tips for Laboratory Sample Pulverizers

Laboratory sample pulverizers are vital for many scientific applications. They prepare samples for testing by grinding them into fine powders. However, proper maintenance is essential for optimal performance. Regular cleaning is one of the simplest ways to extend the life of your pulverizer. After each use, residues should be removed. Leftover materials can contaminate future samples.

Keeping the pulverizer's components in good shape is crucial. Check the blades or grinding plates periodically for wear and tear. If they appear dull, it may be time for a replacement. Lubricating moving parts can prevent friction and potential breakdowns. Using the wrong lubricant could lead to more problems than solutions.

It’s important to monitor the machine's performance. Unusual noises or vibrations can signal issues. Don’t ignore these signs. Conducting routine inspections can help catch problems early on. If something seems off, consider reassessing your maintenance routine. Being attentive can save time and resources in the long run.